Time to get the printers warmed up!!

In this tutorial I will show you how to assemble the back covers. It is pretty easy if your prints are correctly printed without warping otherwise, you will have a hard time to join all the parts together.

Some of these parts require support during 3D printing, so please check the bellow list.

Download STL from the Gallery

Before printing all the parts you should print the CALIBRATOR, to check if your parts will fit together. If you have a very hard time putting those parts together, adjusting the horizontal expansion setting of your slicer software can solve that, this setting can vary depending of your slicer and printer but users report to set it at -0.15 is a great place to start.

An infill of 30%, wall thickness 2.5mm, best with no raft, no support(unless specified), use a brim for big parts to avoid warping.

Here is the list of parts and the number of prints needed for the back:

- 1x BackClaviHolder (add support)

- 1x BackCoverBottomLeft (add support)

- 1x BackCoverBottomRight (add support)

- 1x BackCoverBottomMid (add support)

- 1x BackCoverTopLeft (add support)

- 1x BackCoverTopRight (add support)

- 1x BackCoverTopMid (add support)

- 1x BackCoverLowLeft (add support)

- 1x BackCoverLowRight (add support)

- 1x BackHipsLeft (add support)

- 1x BackHipsRight (add support)

- 1x BackHipsMid (add support)

- 1x BackHolderCenterLeft

- 1x BackHolderCenterRight

- 1x BackHolderCenter

- 1x BackHolderLowLeft

- 1x BackHolderLowRight

- 1x BackSideHolderLeft

- 1x BackSideHolderRight

- 1x BatteryHolderLeft

- 1x BatteryHolderRight

- 2xBatteryPusher

- 1x BackDoorRight

- 1x BackDoorLeft

- 1x BackDoorClip

- 1x BackPower

Step1:

Trim all the support off your prints and make them all clean!

If you plan to use extra servos for the neck (Bob Houston upgrade) You will need to rotate upside down your Arduino and Nervo boards, mainly because the USB cable is not well positionned.

If you don’t plan to use the servo upgrade, you can start by adding and gluing all the holders to the torso plates.

You might want to check the 3D sketchs to see what part goes where!

InMoov, back holder top

These small parts should be glued. Nota: the files you have printed will look different because I updated them to allow the set up for extra neck servos.

InMoov back holder Mid

The middle should also be glued. If your parts are printed in ABS, you can use acetone.

InMoov holder Low

Same thing here for the low holder, Use glue or Acetone

InMoov Back holder center

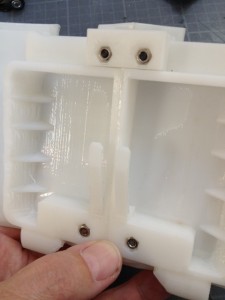

You need to add screws to fix the center holders. But it also can be glued.

Step 2:

It is better to assemble the parts directly on site to avoid deformations during the time it dries out. Use some clamps to glue and hold the parts together, this will seriously help to make proper fittings.

Add the screws and bolts to fix all the parts together.

Add the screws and bolts to fix all the parts together.

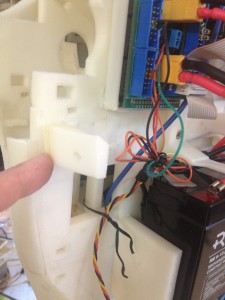

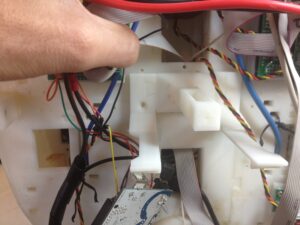

Keep on adding more parts, these should NOT be glued, because it allows you to keep access if ever you want to modify things behind the switchs.

Keep on adding more parts, these should NOT be glued, because it allows you to keep access if ever you want to modify things behind the switchs.

You have the option to add 2 switches on each side of the robot for various purposes. I use one as main shut down., another one is to power up the mini Amplifier. The third is to power up the wheel mobile base and the fourth is currently vacant. These switches are available in most spare electrical stores and on internet of course.

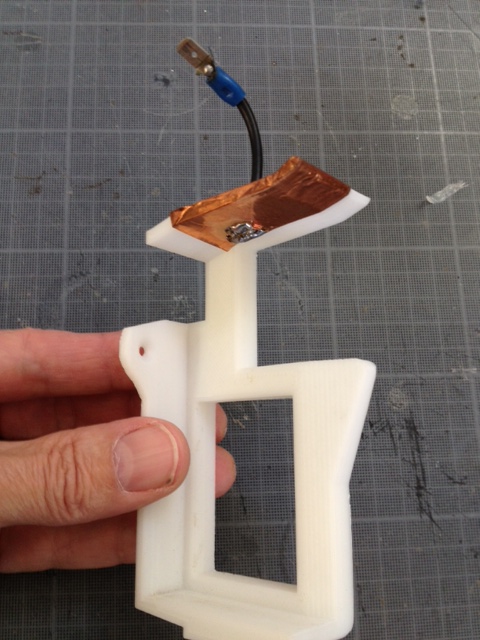

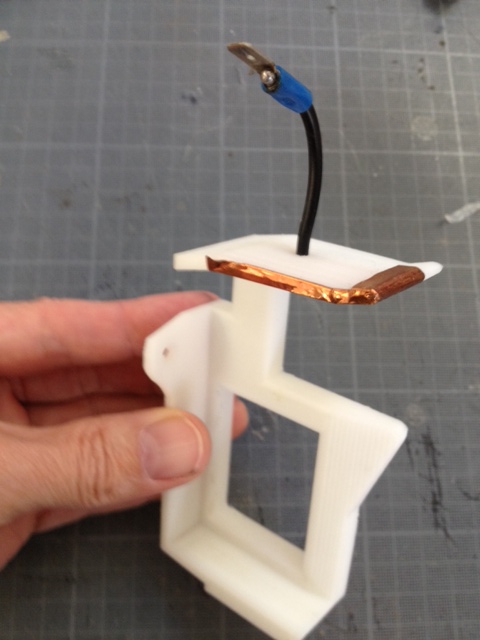

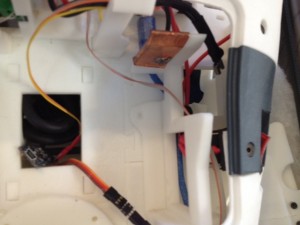

If you had already printed the Battery holders of the previous version, you can saw them or re print my new version. The new version of Battery Holders allows you to add a copper sheet on the top where the battery slides. Therefore when pushing the battery into the back, it can automatically give the power without having to connect wires everytime you switch battery.

I fixed my USB hub on the bottom of the back. You can see it is a 8 port HUB USB3.0. Somebody made a nice fix to hold the USB hub in the back of InMoov here.

I fixed my USB hub on the bottom of the back. You can see it is a 8 port HUB USB3.0. Somebody made a nice fix to hold the USB hub in the back of InMoov here.

On the right side (blue) it is my USB Soundcard. On the top left, hanging,(in red) there is the audio jack that goes from the mini Amplifier to the USB Soundcard.

Now you can add the bottom part of the back. Again, I recommend gluing the parts on site to avoid deformations.

Now you can add the bottom part of the back. Again, I recommend gluing the parts on site to avoid deformations.

Glue the Battery Pusher inside the back door.

Glue the Battery Pusher inside the back door.

Connect the mini USB OTG cable to your Thinkpad Lenovo 8″ Tablet (see BOM for part list) and place and press fit on the back of your InMoov.

Connect the mini USB OTG cable to your Thinkpad Lenovo 8″ Tablet (see BOM for part list) and place and press fit on the back of your InMoov.

You might notice that there is no gap to connect the audio output, the reason is because I’m using a USB soundcard 3.0 which allows me to send the audio to the mini Amplifier. The USB soundcard also has an microphone input, which is handy in some environments. So all sound is treated through USB.

Check for the Upload & Update page in the gallery.

Have fun and be kind to your InMoov!!