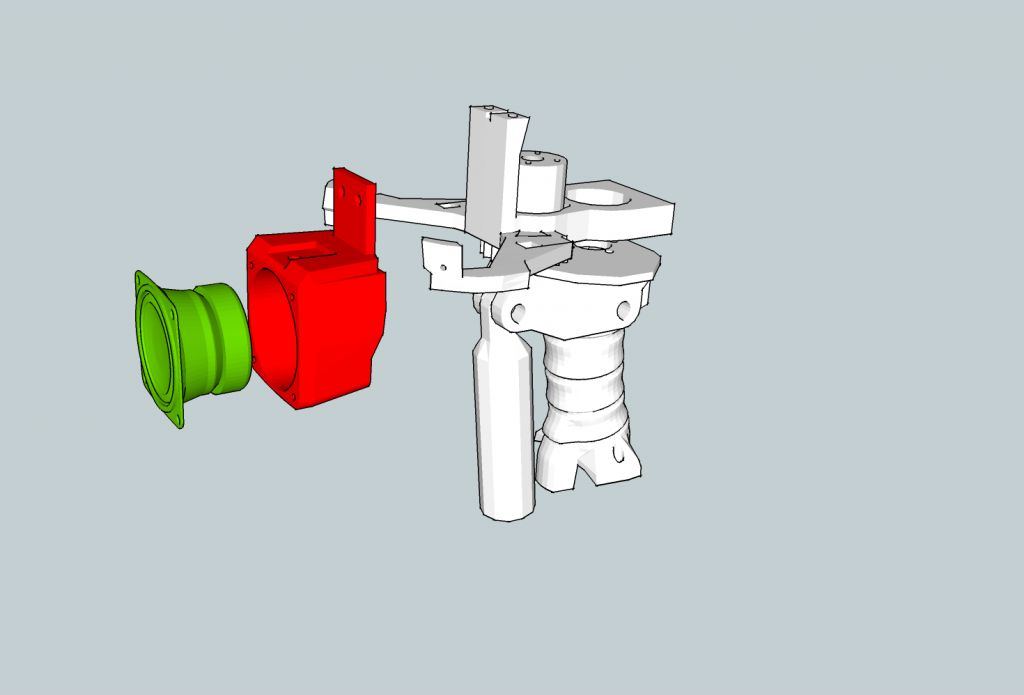

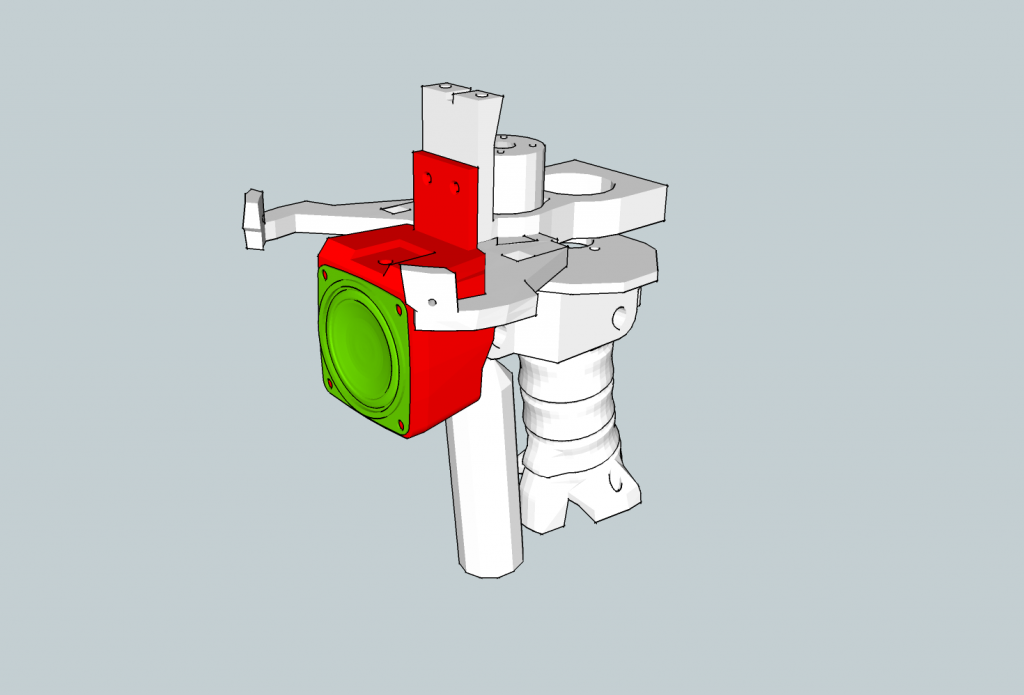

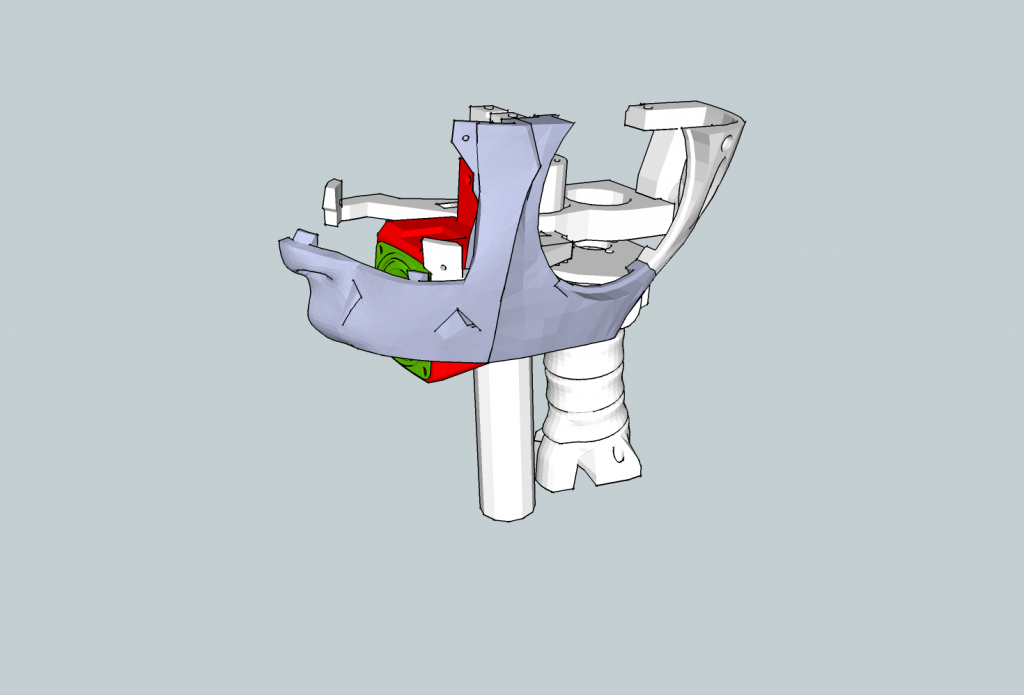

Assembly of the head.

Important notice: I have created a new head model called i2Head. It is much more complex and requires casting silicon, here is the link: https://inmoov.fr/i2head/

This original model is fairly simple, so I won’t extend myself on this part.

Be sure to assemble the mechanisms that are inside the head before putting the outside shell together.

Download STL from the Gallery

Before printing all the parts you should print the CALIBRATOR, to check if your parts will fit together. If you have a very hard time putting those parts together, adjusting the horizontal expansion setting of your slicer software can solve that, this setting can vary depending of your slicer and printer but users report to set it at -0.15 is a great place to start.

An infill of 30%, wall thickness 2.5mm, best with no raft, no support(unless specified), use a brim on big parts to avoid warping.

- Skull and ears

- Face and Jaw

Thanks to Bigfilsing for this video tuto.

Thanks to Shido for this video tuto.